Don’t compromise with Safety!!!

Leaksealing is performed online and onsite. In other word, technicians are working on live leaks with pressure and high temperature conditions.

Petroseal technicians seal leakages on steam and also on hazardous products such as chemicals, acids, flamable products…therefore special care is required !

Thanks to 40 years of experience in leak sealing and thousands of jobs performed worldwide, Petroseal has developed leaksealing products and procedures for any kind of devices (gaskets of flanges, pipes, leaks on welds, valve gland packing…) and for different kinds of fluids.

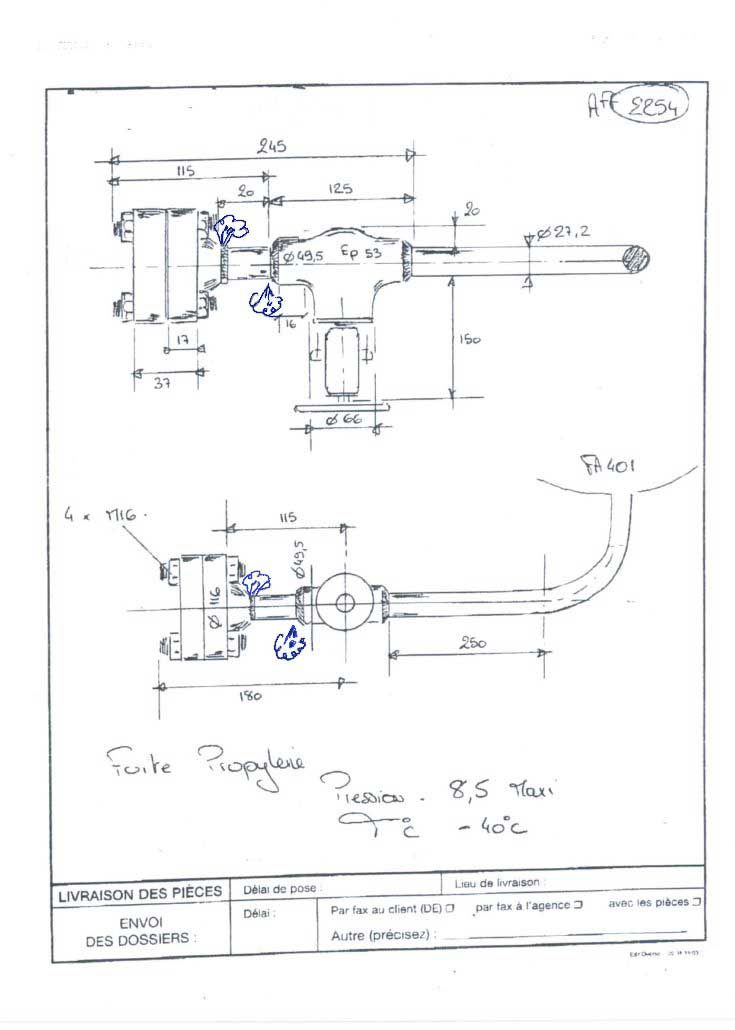

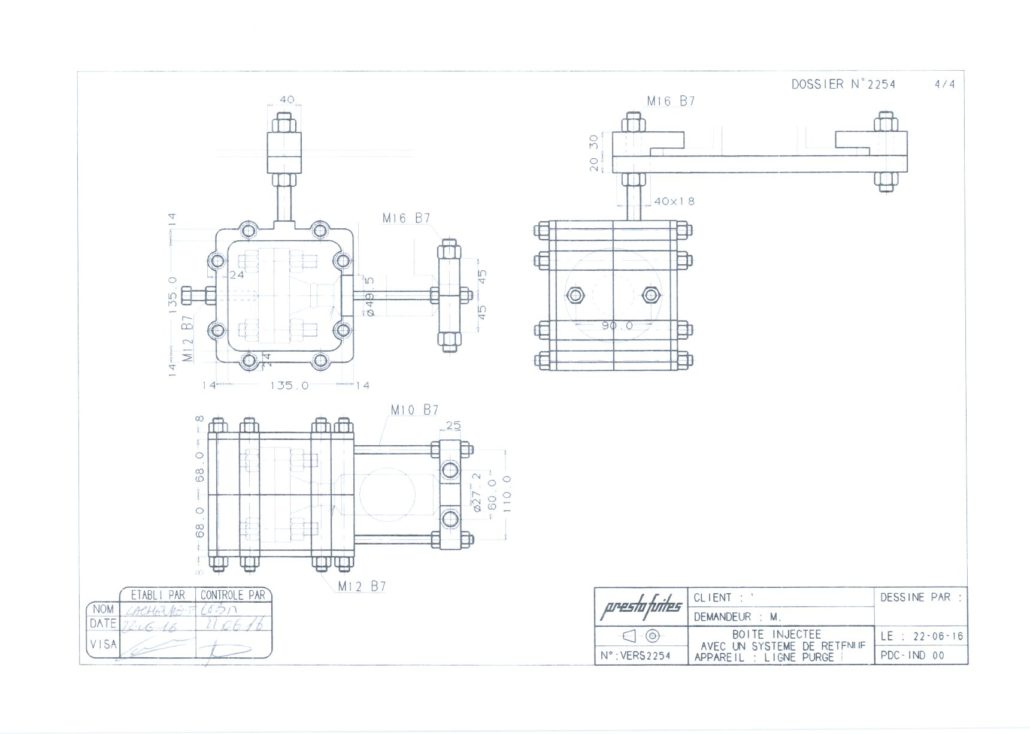

Petroseal leaksealing procedures are essential for the safety of the material as well as for the safety of the technicians. To achieve this, Petroseal designs a dedicated metal enclosure, with safety reinforcement for every case. For instance, in the unlikely case of a flange stud/bolts failure (due to corrosion, material weakness, un controlled torquing or overstress during compound injection…), the reinforcement system holds the flange assembly to prevent any potential dismantling…and its hazardous consequences!!!

Caution! The design of the enclosure (box, clamp, elbow…) and the selection of the right raw materials (carbon, alloy or stainless steel) have to be carefully considered. They need to fit perfectly to the field situation and handle the operating pressure, temperature and fluid nature. That’s why Petroseal supplies calculation and design for most cases based on on the following construction codes for pressure vessels CODAP 2000 (European Norms) and American code ASME Section VIII.

In other word, Leaksealing is an engineered solution that needs to be performed by well trained mechanical maintenance expert. We, as Petroseal, can train your staff whether you are a contractor or a maintenance department.

Link : Our page training

Link: Our Processes