Onsite Dimensions : The key point for a successful Job

Remember there is no standard situation….and no standard solution!

There are always many parameters to consider. Is there any obstacle around, such as a wall, a pipe, instrumentation that could complicate job conditions?

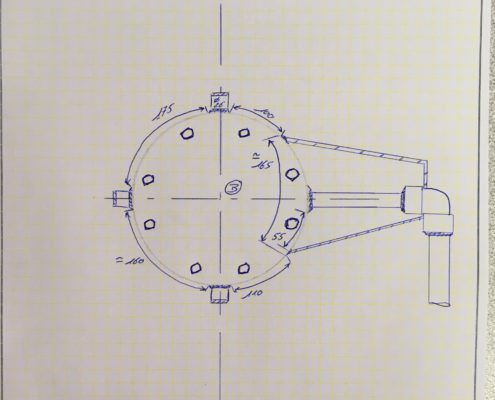

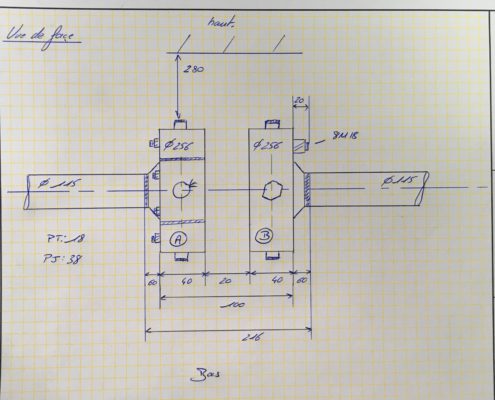

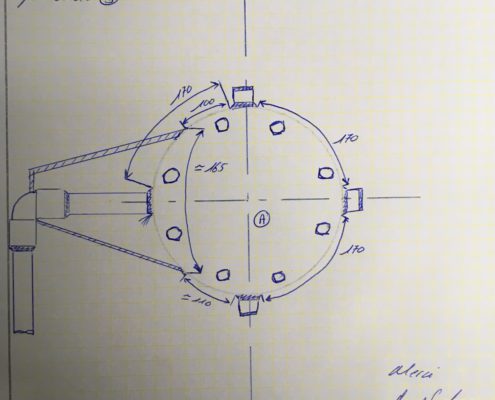

Below, is the perfect illustration of situations we daily face.

Conditions :

- Media : Steam;

- Operating Pressure : 20 bar;

- Operating Temperature : 200°C

- Industry : Petrochemical Plant, in France

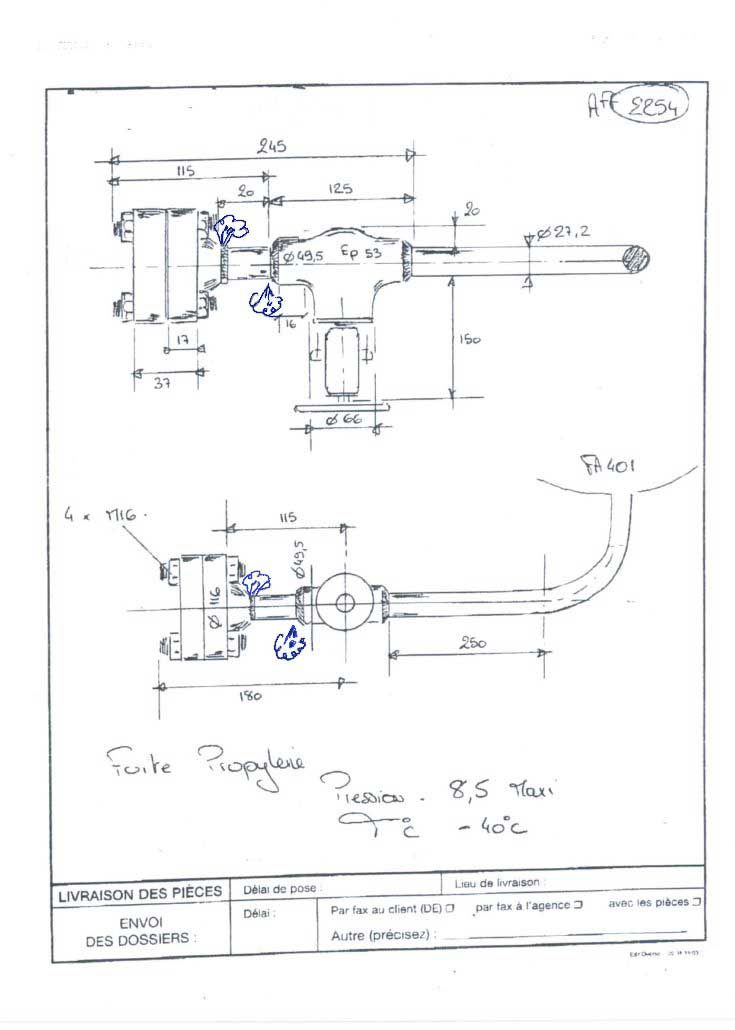

To seal this leak, as any other leak, the sealing enclosure has to fit the device perfectly…that’s why we only rely on accurate onsite dimensions and never on theoretical data and/or ISO drawings.

Look at what is expected in such a case:

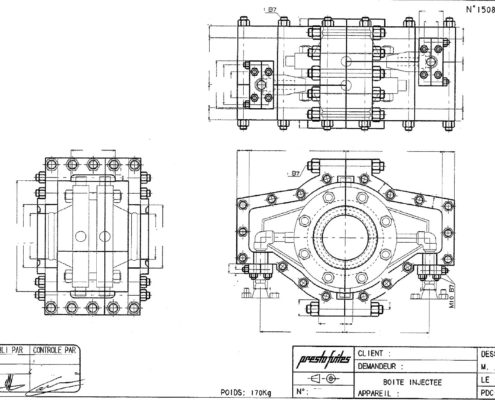

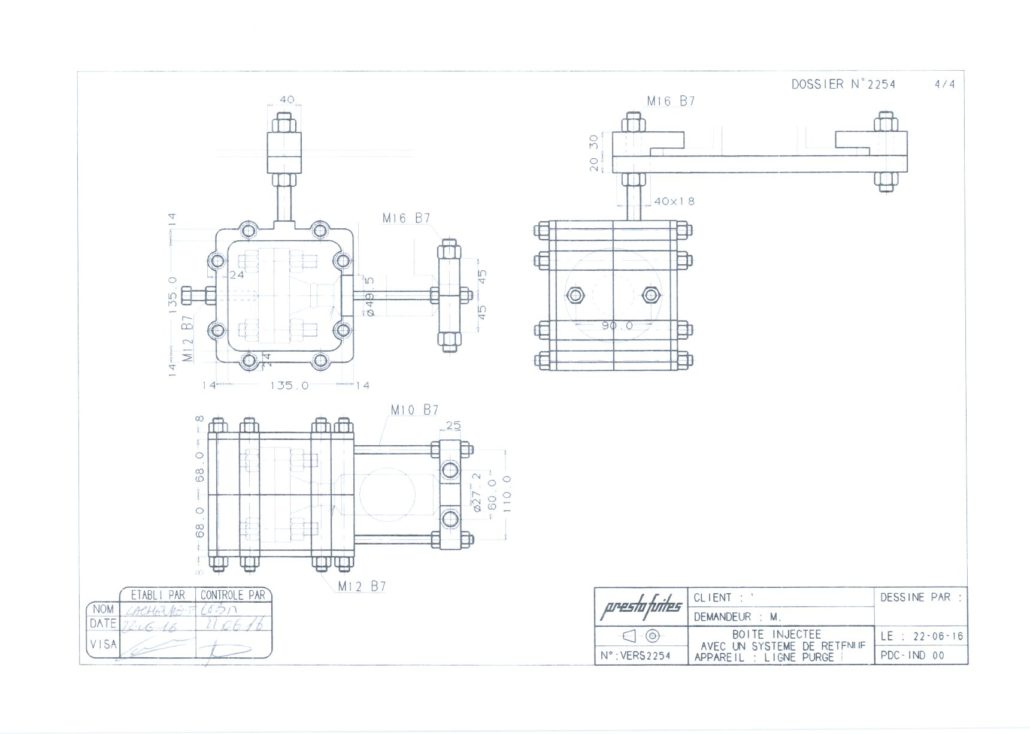

Thanks to the information gathered …Petroseal Engineering department has calculated and designed a dedicated enclosure, taking into account the usual parameters : operating pressure, operating temperature, fluid, material of the equipment, … but also and above all the complexity the device itself and the obstacles around.

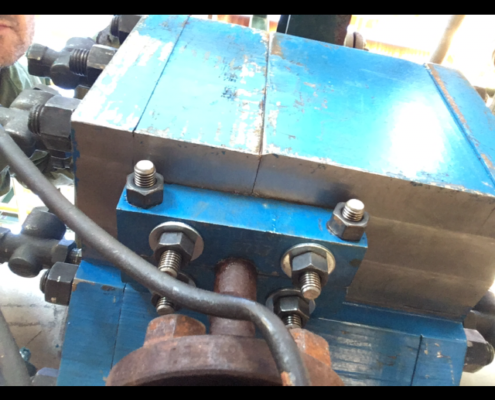

Once the sealing enclosure is approved and manufactured, Petroseal service company or its partners take care of the onsite part set it up and injection job. This part of the job is performed under pressure using dedicated injection equipment and following Petroseal injection procedures.

As a summary, no job can be performed successfully without accurate and complete onsite dimensions!

Onsite expertize and dimensioning is part of our training program. Don’t hesitate to contact us for more information.

Link to our processes and training page : https://leaksealing.com/applications/