‘’Made in France’’ sealing compounds

Manufacturer since 1974

PROVEN FORMULATIONS FOR ALL TYPES OF LEAKAGES

STEAM – WATER – AIR – ACIDS

HYDROCARBONS BYPRODUCTS

READY TO BE INJECTED SEALING COMPOUNDS

Our sealing compounds are half-pasty and don’t need to be pre-heated before injection

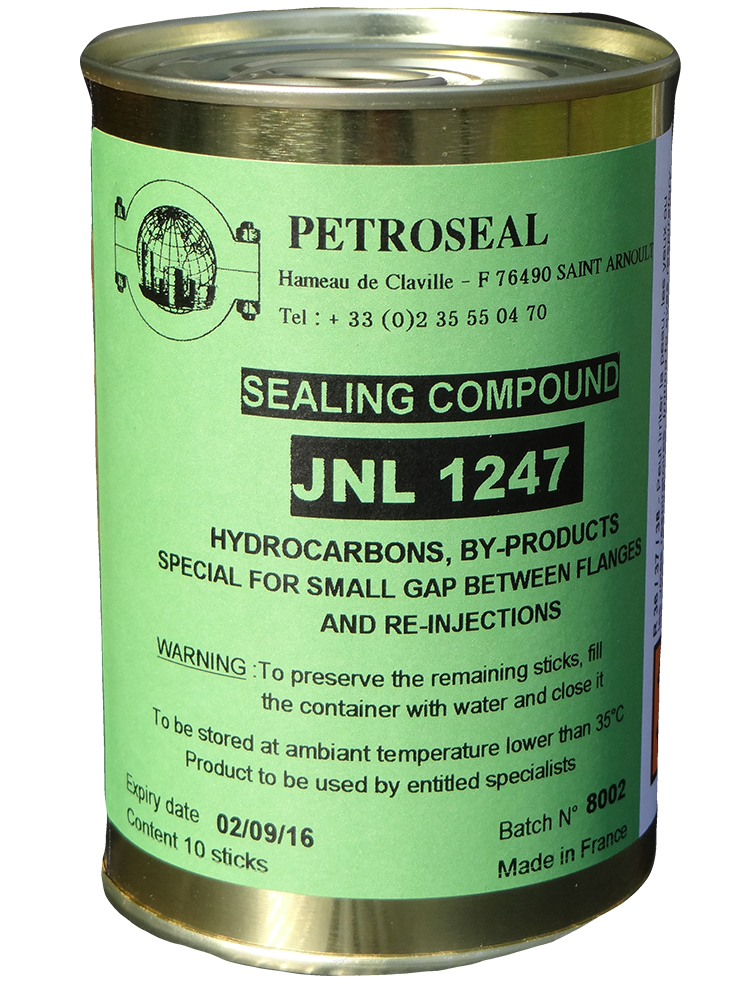

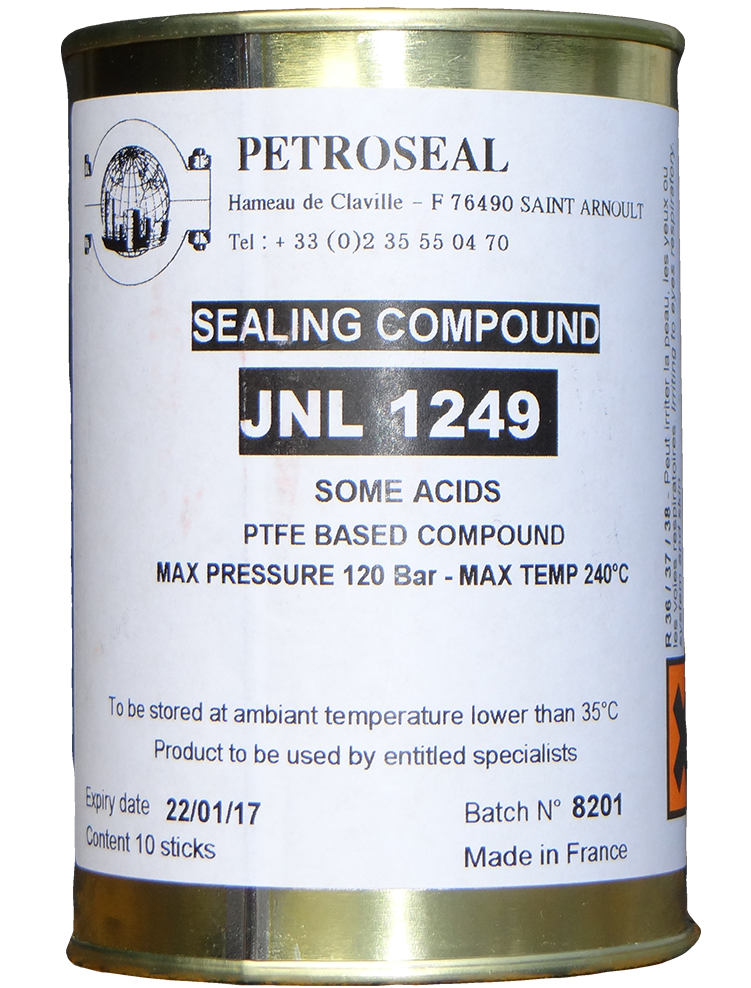

Traceability

Each of the 70 000 cans we yearly produce bears a batch number, an expiry date and a legal labelling.

Technical Data Sheets in various languages and Safety Materials Data Sheets complying with regulations applicable to mixtures and chemical preparations.

PACKAGING AND SHELF LIFE

PETROSEAL’s injectable sealing compounds are packed into metallic cans and enjoy a 2 year shelf life (3 years for nuclear grade compounds)

Last minute or planned requirements ? Whatever your needs, Petroseal always keeps a permanent and consistent stock of the most frequently used sealing compound for immediate shipment.

Cans sold worldwide over the last 20 years.

a stick of product is injected somewhere in the world

countries our products and technology are applied

An in-house production run under the highest quality controls

From the mixture of selected raw ingredients to the final packaging, our laboratory technicians rigorously conform to the compounds formulas and manufacturing processes developed by the inventor

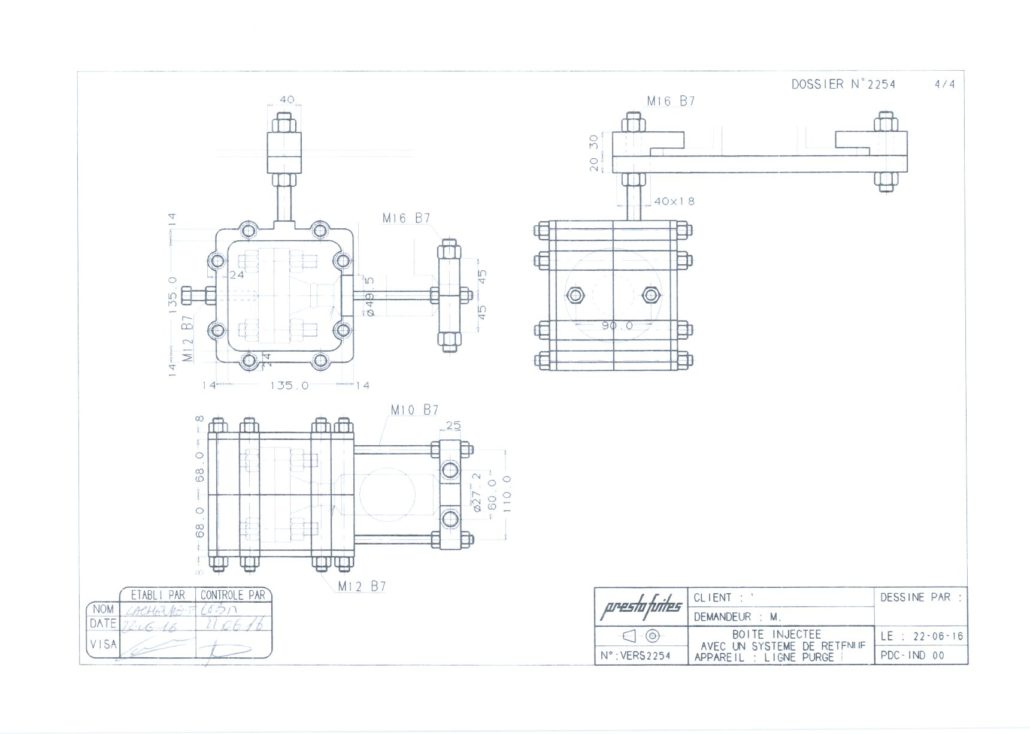

INJECTION EQUIPMENTS

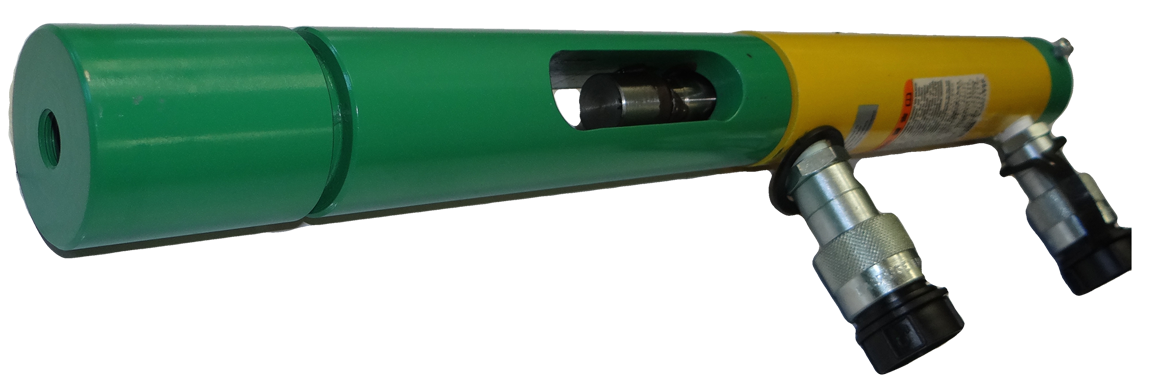

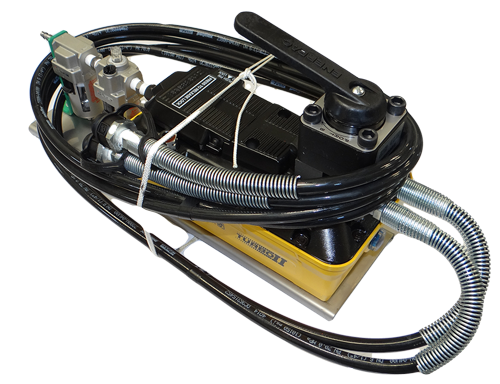

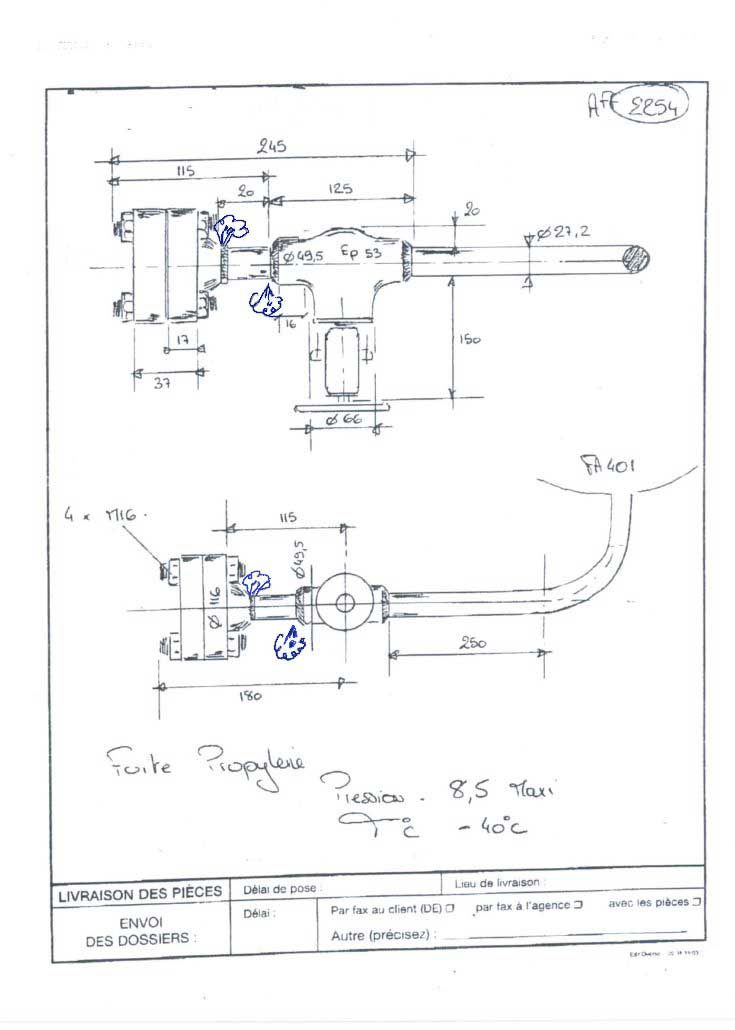

To inject our sealing compounds, we use hydraulic equipments composed of twin effect pumps and jacks. This ‘’twin effect’’ system, exclusively designed by Petroseal, is the only one allowing a ‘’continuous’’ sealing compound injection.

We offer various combinations according to the job conditions: for example, the hand pump with a ‘’1 stick’’ jack ensures a controlled compression of the sealing compound inside the enclosure whereas a pneumatic pump with a ‘’4 stick’’ jack allows a fast filling of significant compound volume.

Pompe Manuelle

Vérin d’injection 1 baton

Pompe pneumatique

Vérin d’injection 4 batons

Get the technical documentation

For all our sealing compounds, get the list of every product and technical specifications that fit your needs.

Premouled Solutions

Ideal for severely corroded pipes that could not stand any compound injection pressure. Both for straight portions and for 90º long radius elbows

No in-situ compound injection : premoulded boxes are easily and quickly installed !

Elbow standard sizes

1/2″ to 8″

Straight standard sizes:

1/2″ to 10″

ABOUT PETROSEAL

Designer, manufacturer and supplier of home made sealing compounds worldwide

PETROSEAL

B.P. 104

F-76430 Saint-Romain-De-Colbosc

France

Tel: +33 2 35 55 04 70

Fax: +33 2 35 20 67 26

FIDGI GROUP (HOLDING COMPANY)

Parc d'Activités de l'Aérodrome

BP 104 - 76430 ST ROMAIN DE COLBOSC

France

Functional Always active

Preferences

Statistics

Marketing

[ninja_forms id=1]

[ninja_forms id=1]